Choosing the wrong cup coating can hurt your brand. Some are bad for the environment, others don't perform well, and the costs can really add up.

The best coating depends on your needs. PE is cheapest, PLA is compostable, and new water-based coatings are easily recyclable. Understanding the pros and cons of each is key to making a smart choice.

For over 15 years, I've seen how much the technology inside a simple paper cup has changed. The coating—that invisible inner layer—is the most important part. It's the difference between a happy customer and a leaky mess. It also tells a story about your brand's commitment to sustainability. Many of my clients get confused by all the options, from traditional plastic to new "plastic-free" technology. Let's break down the five main types so you can choose with confidence.

What is the standard PE coating that everyone uses?

You need a reliable cup that just works, especially for hot coffee. You've heard about new options but wonder why the traditional coating is still so popular.

PE (Polyethylene) coating is a petroleum-based plastic liner. It is extremely effective, durable, and the cheapest option, which is why it has been the industry standard for decades.

When I first started in this business, PE was the only option. It's a true workhorse. We apply a very thin layer of this plastic to the paperboard and use heat to seal it. This creates a completely waterproof barrier that can handle everything from boiling hot coffee to ice-cold soda without any issues. It’s a proven, reliable technology, and because it is produced in such massive quantities, it is the most affordable coating on the market. For a business owner focused purely on performance and low cost, PE seems like an obvious choice.

However, its biggest advantage is also its biggest problem. Because it is a plastic film bonded to paper, it is very difficult to recycle. You need a specialized facility to separate the plastic from the paper fibers, and most cities don't have one. This means that almost all PE-lined cups end up in a landfill. So, while it's a great performer, it is the worst choice for the environment.

Is PLA coating the best eco-friendly choice?

You want to offer your customers a truly green option. You've heard that PLA is made from plants, but you're not sure how that makes it better.

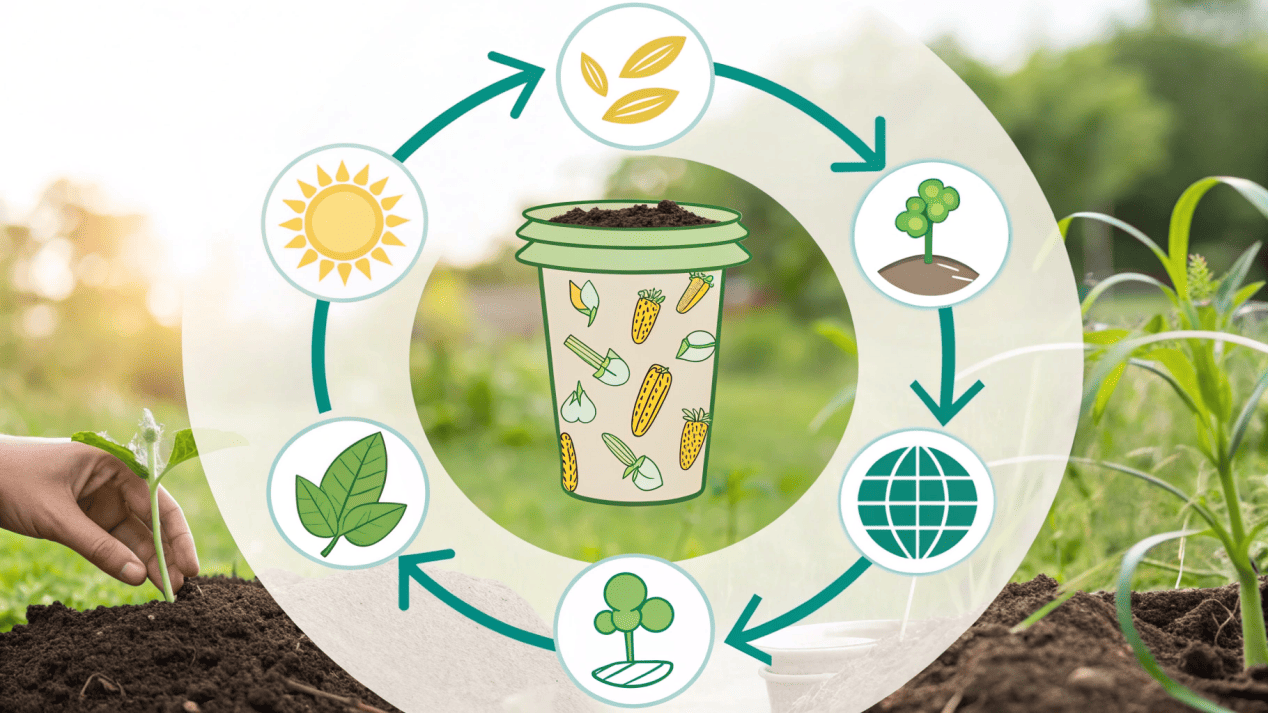

PLA (Polylactic Acid) is a bioplastic made from renewable resources like corn. It is commercially compostable, making it a great eco-friendly alternative to traditional plastic, but only if disposed of correctly.

PLA was a game-changer when it arrived. I remember how excited my most environmentally-focused clients were. Finally, we had a coating that performed just like PE but was made from plants, not fossil fuels. It creates a strong, reliable barrier for both hot and cold drinks. The big win for PLA is what happens after it's used. It is designed to be sent to an industrial composting facility, where heat and microbes will break it down completely into organic matter within about 90-180 days. This creates a circular system.

The catch is that PLA's benefits depend entirely on having access to these industrial composting facilities. You can't just throw it in your backyard compost bin. If a PLA cup ends up in a landfill, it can release methane, a potent greenhouse gas. And if it gets mixed into the regular plastic recycling, it can contaminate the entire batch. So, before you choose PLA, you must check if your city has the right composting infrastructure. If it does, PLA is one of the best sustainable choices you can make.

What is this new "recyclable" aqueous coating?

You want a simple, green solution for your customers. Dealing with special composting facilities seems complicated, and you're looking for a cup that can just go in the paper recycling bin.

Aqueous, or water-based, coating is a newer "plastic-free" layer. It is designed to break down in water during the re-pulping process, so the cup can be recycled with regular paper and cardboard.

This technology is causing a lot of excitement in the industry right now. I have several clients who are switching to it because of its simplicity. Instead of bonding a plastic film to the paper, we apply this water-based solution like paint and then dry it. This forms a thin, protective barrier that holds liquid well. The magic happens at the recycling plant. During the re-pulping process, where paper products are mixed with water to create a slurry, this coating easily disperses. This means the paper fibers can be recovered and made into new products without any special equipment.

This is a huge advantage because it fits into the recycling systems that already exist everywhere. It allows you to honestly tell your customers that the cup is "plastic-free" and can be recycled. The main drawback is that it is a newer technology. The performance, especially with very hot or acidic drinks, is still being perfected. It can also be more expensive than PE, but for many businesses, the simple recycling story is worth the cost.

Is there a coating that's high-performance and recyclable?

You love the idea of a recyclable cup but can't risk any performance issues. You need a cup that is as strong as a traditional PE cup but as green as a recyclable one.

Yes. Advanced water-based barrier coatings (WBBC) offer performance closer to plastic while still being fully recyclable in standard paper streams. It's the premium, cutting-edge "best of both worlds" solution.

WBBC is the next evolution of aqueous coatings. Think of it as Aqueous Coating 2.0. As a manufacturer, this is where we see the most innovation. Engineers have created more advanced recipes for these water-based coatings, using a special blend of polymers and additives. This creates a much stronger barrier against moisture and grease, making it perform almost as well as a traditional PE lining. The best part is that it is still designed to break down easily in the re-pulping process, making it fully recyclable.

This is the ideal solution for businesses that demand the highest performance but also want the strongest environmental credentials. The trade-off is cost. As a cutting-edge technology, it is often the most expensive option available. However, for a premium brand that wants to lead the market in sustainability without compromising quality, WBBC is the clear winner. It solves the performance-versus-recycling dilemma.

Why do cold drink cups need a double coating?

You've noticed that cups for iced coffee and soda feel thicker and glossier. You're wondering why they need a special coating and how that affects their environmental impact.

Cold drinks create condensation on the outside of the cup. A double coating—one layer inside and one outside—prevents this moisture from making the cup weak and soggy, ensuring it stays strong.

This is a great question that gets into the physics of an ice-cold drink. While a single inner coating is enough to hold the liquid inside, it doesn't solve the problem of condensation. On a humid day, a cold drink will "sweat," and water droplets will form all over the outside of the cup. This moisture can soak into the paper fibers from the outside, making the cup lose its structure and become soft and flimsy.

To prevent this, we use a double coating. We apply a waterproof lining to the inside (usually PE or PLA) and another one to the outside (almost always PE). The inner layer keeps the drink in, and the outer layer protects the cup from condensation. This makes the cup extremely durable and perfect for iced drinks. The environmental downside is significant. A cup with two layers of PE plastic is even harder to recycle than a standard single-coated cup. It contains more plastic and is one of the least eco-friendly options, even though it performs very well.

Conclusion

Choose your cup coating wisely. Consider performance, cost, and your local recycling options to find the best fit for your business and tell a powerful story to your customers.