You've seen the news: the iconic foam Cup Noodles is gone. This is more than a packaging change; it's a huge shift, and it signals a future you must prepare for.

Nissin is switching to paper to meet powerful consumer demands1 for sustainability2 and convenience. The new paper cup is microwavable3, made from recycled materials4, and tells a much stronger eco-friendly story.

It is one of the most famous packages on the planet: the polystyrene foam Cup Noodles container. For over 50 years, it has been a symbol of convenience. But in a landmark move, Nissin Foods is retiring the foam cup. They are replacing it with a new microwavable3 paper-based cup. As a packaging engineer5, I see this as more than a material swap; it is a major shift in the convenience food industry. It is a blueprint for the future, driven by what customers now demand: sustainability2, better function, and safety. For any brand that wants to make a similar move, the challenges are significant. Here is how it is done.

How Can Paper Handle Boiling Water and Microwaves?

Polystyrene foam was a great insulator. But standard paper gets soggy with hot water, and coatings can melt or spark in a microwave, creating a disaster.

Paper handles this by using advanced, heat-resistant coatings. The best options are a PP (polypropylene) lining for its high melting point or an innovative aqueous (water-based) coating for a plastic-free solution.

The main advantage of foam was its excellent insulation and water resistance. To get that same performance from paper, while also making it safe for microwaves, requires advanced material science6. The cup must hold boiling water without getting soft, and it must endure the intense, uneven heat of a microwave. A standard paper cup with a PE (polyethylene) coating cannot do this; the PE lining will melt and warp. As an engineer, these are the solutions I work with to solve this problem.

The current champion for microwavable3 paper containers is PP (Polypropylene) coating7. PP has a much higher melting point than PE. This allows it to stay stable and inert when heated in a microwave. It creates a very strong, food-safe barrier that stops leaks and keeps the cup's structure firm.

The other option is the cutting edge of innovation: Advanced Aqueous Coatings. These are special water-based formulas that we can engineer for high heat resistance. My team and I have developed patented aqueous coatings that make paper cups viable for microwavable3 use. This is a very powerful solution for brands that want a "plastic-free" sustainability2 story.

| Coating Type | Microwave Safe? | Key Benefit |

|---|---|---|

| PE (Polyethylene) | No | Cost-effective for cold/hot drinks. |

| PP (Polypropylene) | Yes | High heat resistance, very durable. |

| Aqueous (Water-Based) | Yes (with special formula) | Recyclable, "plastic-free" story. |

Is It More Than Just Changing the Coating?

You might think you can just swap the coating on a standard cup. But a regular paper cup is not designed for microwave stress and could fail or even cause a fire.

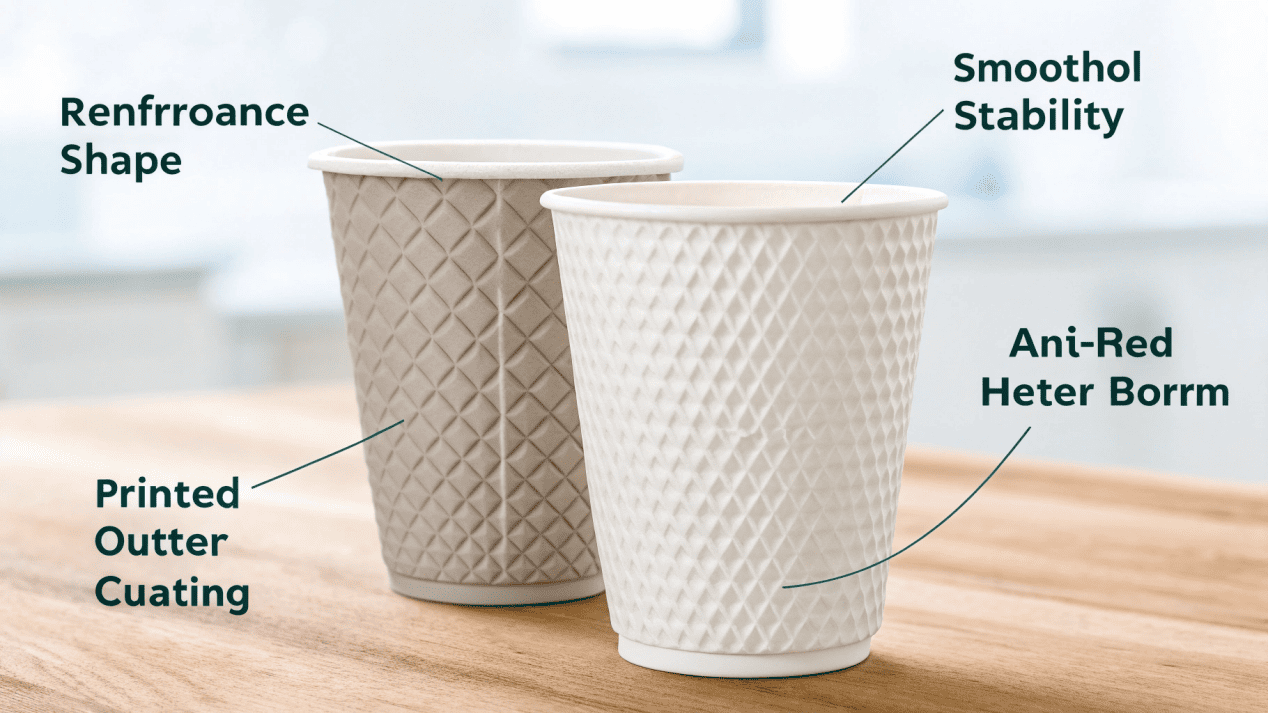

Yes, it is much more than the coating. The entire cup must be re-engineered, including using thicker paperboard, printing with non-metallic inks8, and optimizing the shape for stability and even heating.

I always tell my partners that a microwavable3 paper cup is a complete system, not just a cup with a different lining. The entire design must be re-engineered for safety and performance. If you get this wrong, the cup can become too soft to hold, or worse, cause a safety hazard.

First, the structural integrity9 must be improved. We often use a thicker and denser paperboard than we would for a standard coffee cup. This helps the cup handle the stress of microwave heating and prevents it from becoming too soft or pliable when the contents are boiling hot.

Second, we must use the right inks. This is a critical safety rule: no metallic inks. Any printing or branding on the cup must use special non-metallic, food-safe inks. This prevents arcing or sparks inside the microwave. My expertise in safe, low-migration soy- and water-based inks is absolutely essential for this kind of project.

Finally, the shape and form of the cup itself are often adjusted. We might design a wider base for better stability in the microwave. The overall form may also be optimized to help the microwave's energy heat the contents more evenly. It is a total engineering solution.

How Do You Prove a Paper Cup Is Safe to Microwave?

A "microwave-safe10" logo is easy to print. But one accident caused by an unsafe container can destroy customer trust and lead to huge legal problems for your brand.

You prove safety with undeniable, third-party certifications. An audit from a body like BRCGS verifies that the paper, coatings, and inks all meet strict international safety standards for use under high heat.

The words "Microwave-Safe" printed on a cup are a promise to your customer. That promise must be backed by rigorous, scientific proof. At Haokelao, this is where our deep commitment to global standards becomes our clients' greatest asset. A truly microwave-safe10 product requires a full chain of certified safety that includes the paperboard, the coating, the lid, and even the inks.

Our compliance with FDA regulations and our BRCGS certification11 are the guarantee. We provide our partners with full documentation that all the components meet the strictest international rules for food contact under heated conditions. The BRCGS audit is incredibly detailed; it inspects our entire manufacturing process, from raw materials to factory hygiene, to ensure these safety protocols are followed perfectly, every single time.

On top of this, our internal labs perform rigorous testing. We simulate microwaving the cups over and over. We then test to confirm that there is no material degradation and absolutely no chemical migration12. We provide this data to our brand partners, which gives them—and their customers—complete peace of mind. It’s not just a claim; it’s proven science.

What Is the Impact on the Entire Supply Chain?

You want to switch from foam to paper. But this means finding new material suppliers and buying new machines, which is a huge and very expensive a challenge.

The impact is massive. It requires a complete shift from a petroleum-based material to renewable paper. It also needs entirely different factories and machinery, representing a huge investment and operational change.

When a company as big as Nissin switches from foam to paper, it sends waves through the entire supply chain. It requires a partner who can manage this complexity on a global scale. This is a big part of what we do at Haokelao Packaging.

First, there is the sourcing and material shift. You are moving from a supply chain based on petroleum (for polystyrene) to one based on renewable resources (sustainably-sourced paperboard). As a major global manufacturer, we have already built strong, resilient supply chains for certified paper materials from the best suppliers around the world. We have the volume and relationships to ensure a steady supply.

Second, there is the manufacturing overhaul. The machinery and processes used to form, coat, and print paper cups are completely different from those used for foam. For a brand to make this switch on its own would require a massive investment in building new factories and buying new equipment. Our advanced production lines are already equipped for this. We allow brands to make the switch without that huge capital investment. You can use our factories and expertise.

Finally, there is global distribution13. Nissin is launching this new cup all over the world. Our experience shipping to over 80 countries means we understand all the logistics and regulatory hurdles of a global launch. We ensure the product is consistent and compliant in every market.

Conclusion

Nissin’s move shows the future of packaging is here. This sustainable shift is now a reality. With the right technology and partner, your brand can lead this revolution.

Explore the evolving consumer preferences that shape packaging trends. ↩

Explore how sustainability in packaging can enhance brand image and meet consumer demands. ↩

Learn about the technology behind microwavable paper cups and their advantages. ↩

Discover the environmental benefits and consumer appeal of recycled materials. ↩

Understand the role of packaging engineers in developing safe and effective packaging. ↩

Understand how advanced material science is revolutionizing packaging solutions. ↩

Find out why PP coating is preferred for microwavable containers. ↩

Discover the importance of non-metallic inks for microwave-safe packaging. ↩

Learn how structural integrity affects the safety and performance of packaging. ↩

Discover the criteria that define microwave-safe products. ↩

Learn about the significance of BRCGS certification in food safety. ↩

Find out how chemical migration can affect food safety and packaging. ↩

Explore the complexities of distributing packaging products worldwide. ↩