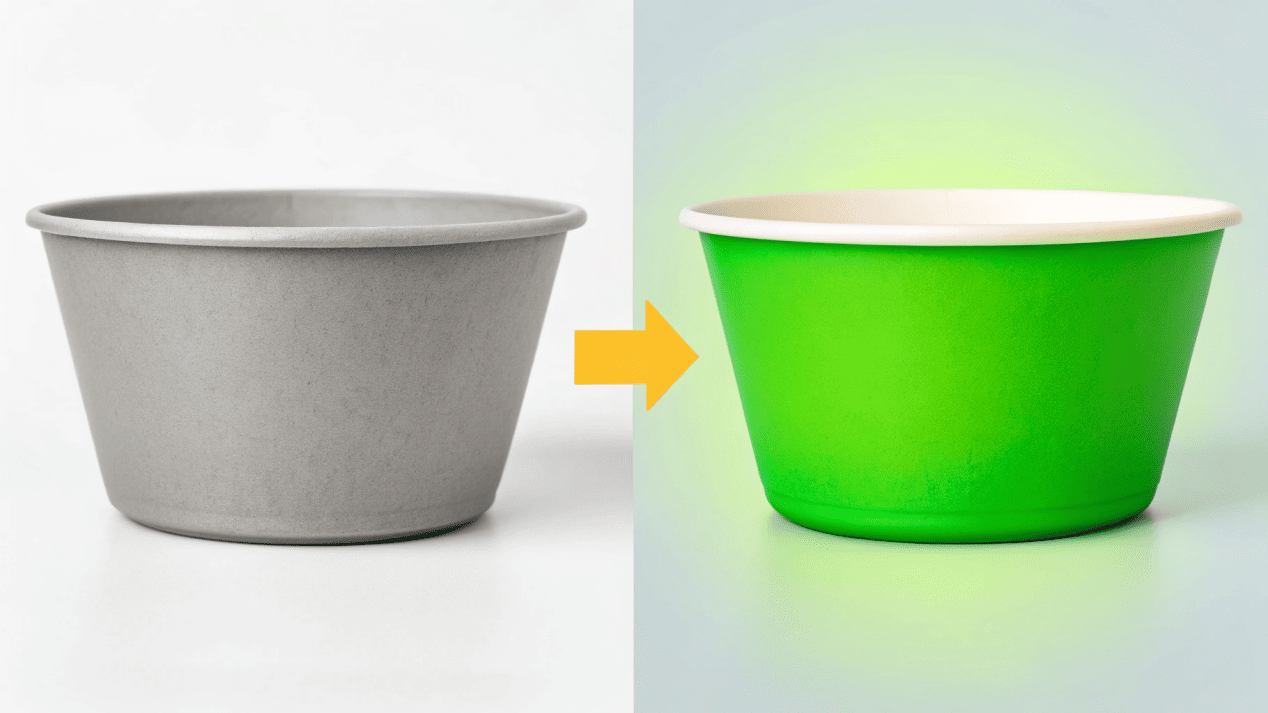

The familiar foam noodle bowl is convenient but a major liability. Consumers now reject single-use plastics, risking your brand's reputation and future sales in an eco-conscious world.

Paper noodle bowls are the future because they align with modern consumer values, meet new global regulations, and offer a premium feel. High-performance paperboard with a compostable PLA lining provides a sustainable, safe, and powerful alternative to foam and plastic.

I recently sat down with a major instant food brand. Their sales were flat, and their social media was full of comments about their styrofoam bowls. They saw the writing on the wall but were scared. "Can a paper bowl really hold boiling water without getting soft?" they asked. They thought the switch was a huge technical risk. This fear is common, but the technology has come so far. That conversation reminded me that my job is to provide confidence, not just containers. Let's break down why this switch is not just possible, but a huge opportunity for your brand.

Why Switch from Foam to Paper Bowls?

You know foam packaging is bad for the environment. But you're worried that changing to paper will be expensive and complicated, with no real return on investment.

Switching to paper transforms a reputational risk into a brand opportunity. It future-proofs your business against plastic bans and allows you to position your product as a premium, sustainable choice that modern consumers prefer.

The argument against foam, or expanded polystyrene (EPS), is now closed. It's made from fossil fuels, it's almost impossible to recycle, and it stays in our oceans and landfills for hundreds of years. For a brand, continuing to use it is like advertising that you don't care about the future. From my perspective as a manufacturer, I see clients making the switch for a simple reason: it’s smart business. It is a strategic move that immediately changes how customers see you. I've worked with brands that made the switch and saw an instant positive reaction from their customers online. They weren't just selling noodles anymore; they were selling a product that people could feel good about buying. This isn't just about being green; it's about being smart.

The Strategic Advantages

- Create a Positive Brand Image: Moving to paper is the fastest way to show your customers you share their values. It's a clear, physical signal that you are a responsible company.

- Get Ahead of Regulations: Governments worldwide are banning or taxing foam and other single-use plastics. By switching now, you avoid the future chaos of forced changes, supply chain problems, or fines. You are protecting your business.

- Justify a Premium Price: A well-designed paper bowl feels better in your hand. It's sturdier and looks higher quality than a cheap foam bowl. This improved experience can help you position your product as a premium item on the shelf.

What Makes a Paper Bowl Strong Enough for Hot Soup?

You pour boiling water into a paper bowl and imagine the worst: a leaky seam, a soft bottom, and an angry customer with a hot mess. The fear of failure is real.

It's not just paper; it's an engineered system. The bowl uses a heavy-gauge, FSC-certified paperboard for structure, combined with a heat-resistant, waterproof lining made from compostable, plant-based PLA for performance and safety.

As a mechanical engineer, this is the part I love. A paper noodle bowl has one of the hardest jobs in packaging. It has to go from your shelf to holding boiling water in seconds, and it has to do it perfectly every time. This is not a simple paper cup. It is a piece of high-performance engineering. Plain paper would turn to mush instantly. The secret is in the layering of materials. First, we start with a very thick, rigid paperboard. Think of this as the skeleton of the bowl, providing all the strength. But the real hero is the lining. This invisible inner layer does all the hard work of holding back the water and heat. For a noodle bowl, our only recommendation is PLA, a liner made from plants. We have tested this combination thousands of times in our lab, ensuring it can handle 100°C water without any issues.

The Science of a Leak-Proof Bowl

- The Foundation: Heavy-Gauge Paperboard: We use a thick paperboard, typically over 300 GSM (grams per square meter), to give the bowl a strong, rigid structure that won't bend or soften when filled. We insist on using paper from responsibly managed forests, proven by FSC certification.

- The Shield: Compostable PLA Lining: On the inside, we fuse a layer of PLA (Polylactic Acid). This is a bioplastic made from plants like corn. It creates a perfect, food-safe, waterproof barrier that can easily handle the heat of boiling water.

- The Certification: Meeting Global Standards: The final product is not just strong; it's certified compostable. This means it meets strict standards like EN 13432 in Europe, which proves that the entire bowl can break down into natural materials in an industrial composting facility.

Do Customers Really Care About Sustainable Noodle Cups?

You wonder if changing your packaging is worth the effort. Will customers even notice, or will they just continue to buy the cheapest and most familiar option?

Yes, they care deeply. Data shows that modern shoppers, especially younger ones, actively look for words like "compostable" and "plastic-free." They are willing to pay more for products that align with their values.

The modern consumer is a detective. They don't just grab a product; they flip it over, read the label, and look for signs that the brand is one they can trust. In my experience, the brands that win are the ones that are transparent. Don't just switch to a paper bowl; tell your customers why you did it. Your packaging is now one of your most powerful marketing tools. I've seen clients add a small leaf icon or a simple phrase like "Plant-Based Bowl" to their design and get an immediate positive response. This isn't just about avoiding a negative (plastic); it's about creating a positive. A well-designed paper bowl doesn't squeak like foam, it feels more substantial in the hand, and it communicates quality before the customer even takes their first bite. You are upgrading their entire experience.

How Can I Trust a New Supplier with My Brand?

You've decided to switch, but the task of finding a reliable supplier feels overwhelming. Choosing the wrong partner could lead to failed products, missed deadlines, and a damaged reputation.

Demand proof. A trustworthy supplier must provide non-negotiable food safety certifications (like BRCGS, FDA), prove their materials are ethically sourced (FSC), and show you their specific experience in making high-heat paper containers.

This is the most important decision you will make in this entire process. A good supplier is more than a factory; they are a partner who protects your brand. When a potential client visits our facility, I don't just show them our machines. I show them our library of certifications. These pieces of paper are our promise to them. They prove that we follow the strictest global standards for food safety and that our raw materials are sourced legally and sustainably. I also encourage them to ask the hard questions. Ask for technical data sheets. Ask for samples you can test yourself with boiling water. Ask for case studies from other brands we have helped. A reliable partner will have nothing to hide. After over 20 years in this business, I know that trust is built on proof, not just promises.

Your Supplier Checklist

- Food Safety Certifications: Ask for proof of BRCGS, FDA, and ISO 9001 certifications. These are not optional.

- Ethical Sourcing: Demand FSC certification to ensure the paper comes from sustainable forests.

- Proven Expertise: The supplier must have specific experience with high-heat containers like noodle bowls. Don't be their first-ever noodle bowl customer.

Conclusion

The move from plastic to paper for noodle bowls is happening now. Leading this change will build a more resilient brand that earns the loyalty of the next generation of consumers.